PATENTED VIBRATION DAMPING SYSTEM

- 6-8 HOURS OF TEMPERING TIME

- HIGH EFFICIENCY

- ENERGY SAVING

- Reduced tempering time of 1-8 hours

- Water addition %8 one pass

- Microbiologically clean product

- Yield increase – up to %1

- Considerable energy saving

- Gentle conditioning, no breakage or abrasion

- Optimal separation of hull and endosperm

- Optimum milling conditions

- Highly cost effective due to even tempering

- Trouble free maintenance

- Quick & easy installation

- Lower construction costs

- No modification

- Registration & control of capacity

- Flexibility

- Special millings possible even on the same day

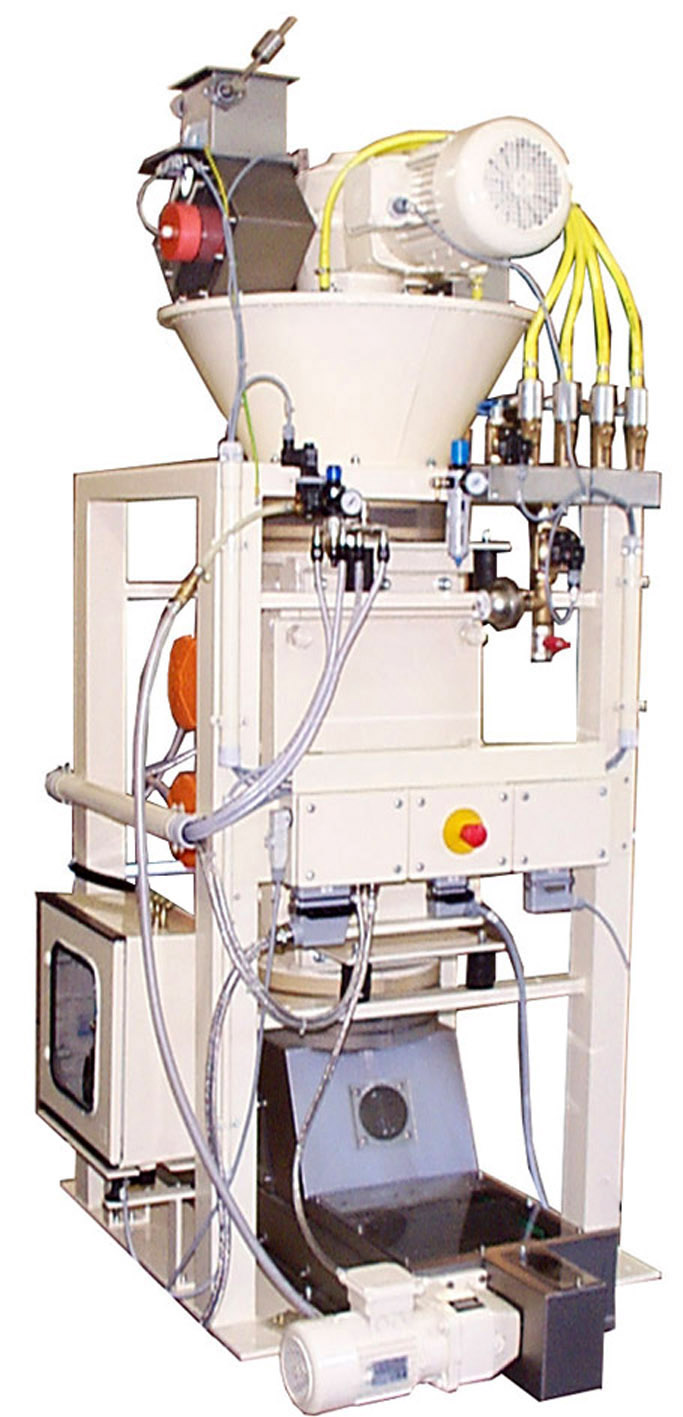

PRINCIPLE OF OPERATION

The premixer device mixes a metered quantity of water with the cleaned grain. The grain/water blend experiences a gentle mixing action that prevents any grain damage or abrasion.

The grain/water blend continuously passes through the vibration channel, which consists of 1 – 12 channels depending on capacity.

The patented vibronet® principle, optimized with special vibrating motors, enables the channel to be vibrated.

This vibration energy eliminates the surface tension of water molecules so that a fiım of water covers the whole grain. The tempering water thus penetrates equally into the hull and through the outer layers into the endosperm.