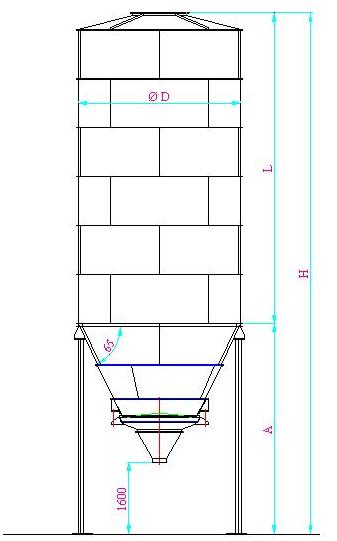

- MODULAR STRUCTURE

- LONG TERM USAGE

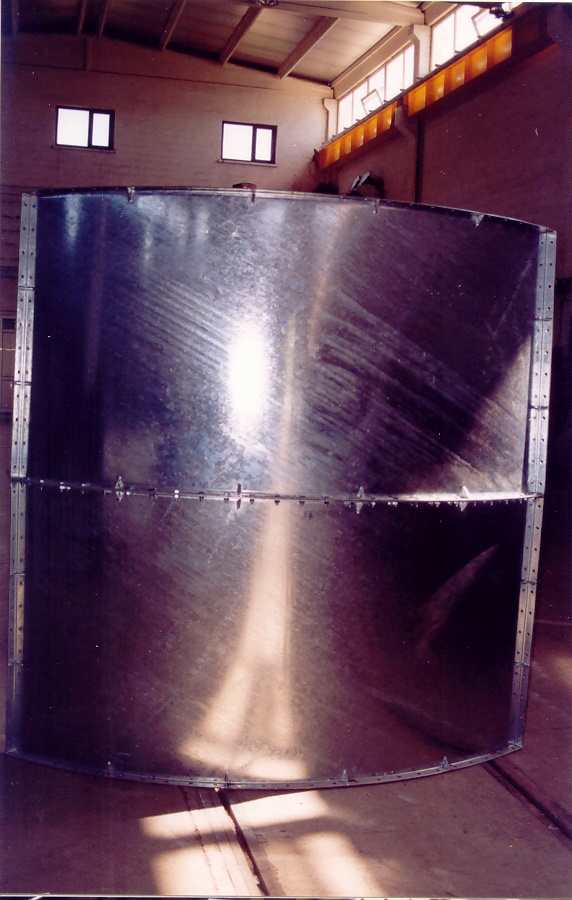

- HOT DIP GALVANIZED DUE TO HIGH MOISTURE

- EASE OF ASSEMBLY

- REGULAR FLOW OF MATERIAL

In flour mills, blending and tempered wheat bins were generally considered to be concrete. However, due to the easy and fast assembly, simple and robust construction advantages, steel bins recently started to be a good alternative. This recent trend is also advised by distinguished flour milling machinery manufacturers. TETA modular steel bins are used as blending and tempered wheat bins and have proven their performance.

TEMPERED WHEAT BINS:

Due to the high moisture content of tempered wheat, standard modular panels after production are hot – dip galvanized to ensure a long life the and corrosion protection. As in blending bins, the discharge section incorporates a special feature to enable first in – first out flow principle.

WHEAT BLENDING BINS:

Modular steel panels, after forming, are painted with industrial paint and externally bolted during assembly. The discharge section incorporates a special feature to enable first in – first out flow principle.